Ludicrously Strong Glue for 3d Prints

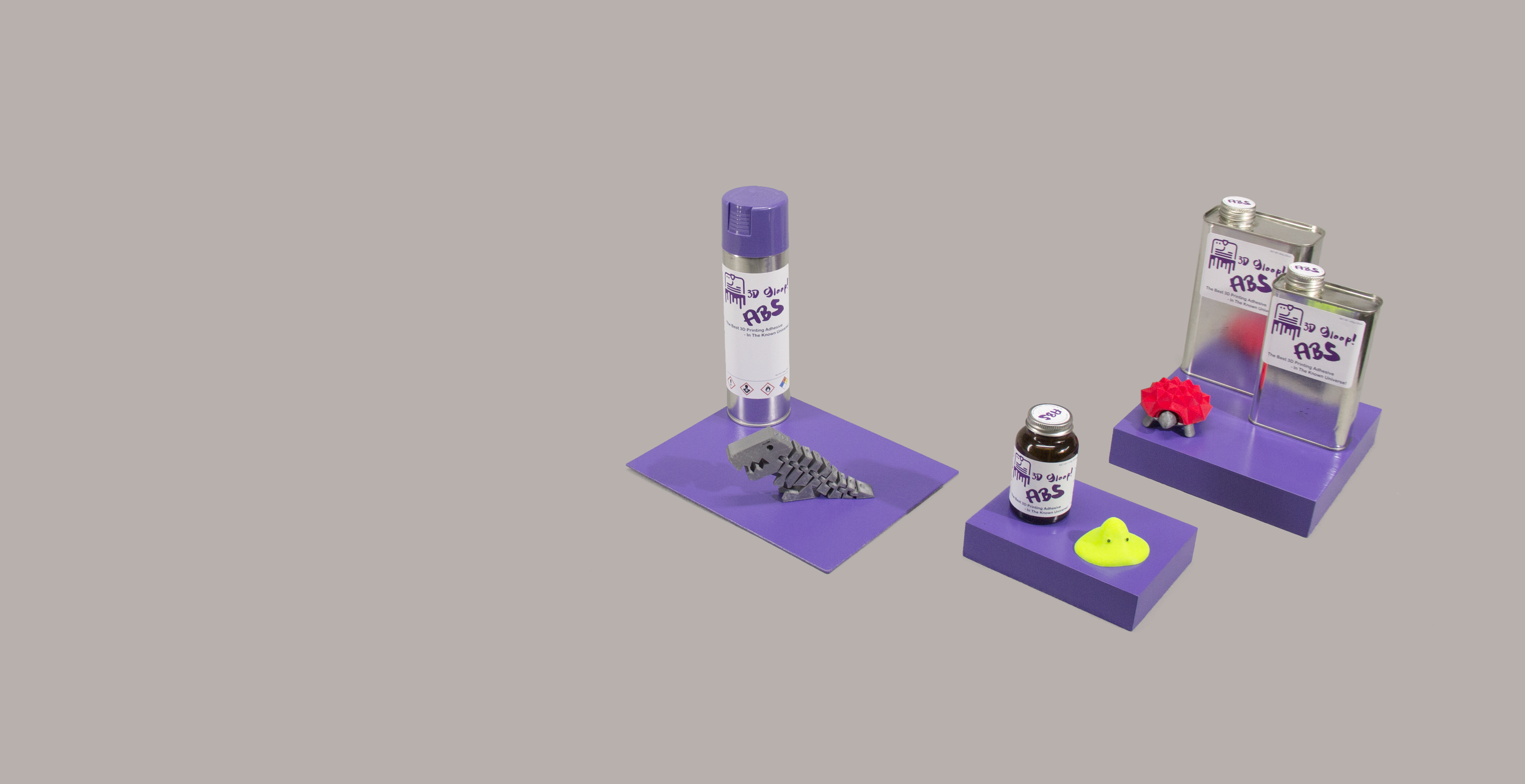

3D Gloop is a specially formulated adhesive compound designed specifically for the plastics used by 3D Printers.

Okay, so we will just say it… 3D Gloop! is hands down the best adhesive for holding your PLA, PET-G, and ABS/ASA prints together. No more messy epoxies or super glues & activators that don’t work. With 3D Gloop! you will get the strongest and most reliable bond compared to any other adhesive on the market!

Don’t just take our word for it. Check out what many popular content creators think of 3D Gloop!

Perfect 3d Prints every time

3D printers are amazing machines that allow us to create and explore the furthest reaches of our imagination. The capability of turning a concept to reality in just a matter of hours is incredibly powerful. - That is, of course, as long as the printer doesn't goof up!

The same 3D Gloop! that is used for gluing your 3D prints can also help increase print adhesion to heated and unheated glass, metal, and even taped build plates on any 3D printer!

Our unique adhesive formula is easily brushed onto the 3D Print or the build surface of a 3D printer. As the adhesive dries, nano-particles constructed from PLA or ABS plastic are suspended in a synthetic elastomer that rapidly polymerizes cementing the nano-particles in place. This rapid polymerization strongly adheres prints together or the soon-to-be printed object to the build surface!